Japan's onshore wind power generation, which began full-scale deployment in the 2000s, now has a cumulative installed capacity well over 5GW, and is expected to reach 18GW by 2030. The country plans to further increase onshore as well as offshore wind power generation in order to achieve carbon neutrality by 2050, but along with new installations, the replacement (upgrading) of currently operating power plants will be essential. We talked to Kentaro HAGA, Yamato IRIE, and Kana YAMAGUCHI from the Wind Power Generation Promotion Project, Project Management Dept., Project Management Div., who are responsible for wind power generation's design at PACIFIC CONSULTANTS, about the challenges of replacement and key points in formulating an implementation plan.

INDEX

- Early onshore wind power generation approaching replacement time

- Reasons why replacement is difficult: Wind turbines becoming larger

- Things to consider when wind turbines get bigger

- Issues in replacing wind power generation equipment

- What PACIFIC CONSULTANTS can do

Early onshore wind power generation approaching replacement time

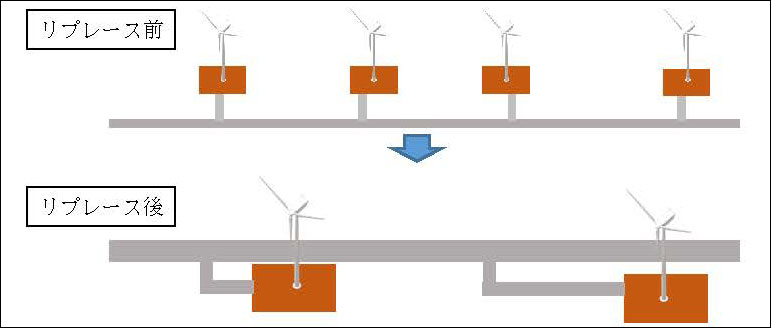

The replacement cycle for wind power generation equipment is said to be approximately 20 years. After operation begins, routine maintenance, statutory periodic inspections, and part replacement as needed are performed. However, after 20 years, power generation efficiency declines due to aging and the risk of breakdowns increases. Therefore, replacement involves replacing the wind turbine itself while maintaining the grid connection and surrounding equipment. Over the 20 years since installation, wind turbines have undergone improvements, increasing power generation efficiency and increasing power generation per unit through larger sizes. Therefore, replacement does not simply replace equipment; it also leads to improved power generation capacity. Another major benefit of replacement is the relatively low burden of investigation and review work and procedures compared to new construction, such as the fact that agreement with local communities has already been obtained and that some environmental impact assessments can be omitted under certain conditions. In fact, many municipal and private wind power plants that began operation around 2000 have already carried out replacements, with the number of such cases increasing particularly from 2022 onward.

However, despite the growing need for replacement, many power plants have been in operation for over 20 years and are struggling to create replacement plans. According to a survey by the Japan Wind Power Association, as of the end of December 2023, there will be 105 power plants (420 reactors) nationwide that have been in operation for over 20 years and have not yet been removed or decommissioned, with a total output of 500,620 kW.

Reasons why replacement is difficult: Wind turbines becoming larger

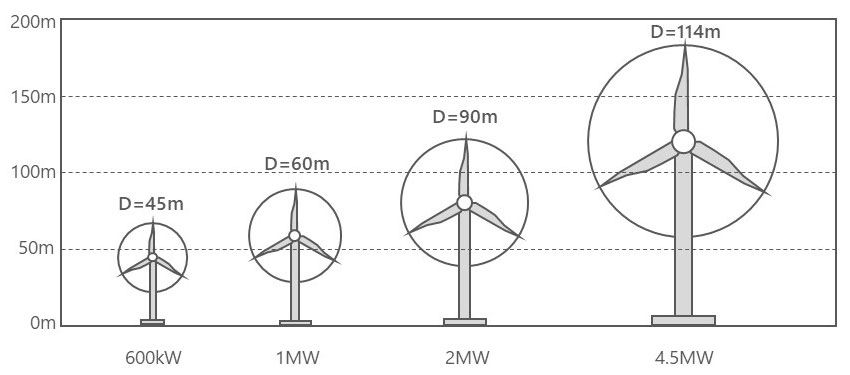

One of the major reasons why replacement is proving difficult is the rapid increase in the size of wind turbines. The energy that wind power obtains from the wind increases in proportion to the surface area of the blade that receives the wind. Therefore, the longer and larger the blades are, the higher the power generation efficiency. Also, since wind blows stronger the higher up in the sky, the higher the height of the wind turbines, the higher the power generation efficiency will be.

The wind turbines at power plants that began operation in the late 1990s and early 2000s, during the early days of onshore wind power generation in Japan, mostly had rated outputs of around 500kW to 1000kW. For a rated output of 1,000kW, the tower was 60m high and the blades were about 60m in diameter. However, for a 2,000kW output, the height was 90m and the blades were about 80m in diameter, and for an output of 4,500kW, the tower was over 110m high and the blades were over 124m in diameter, making them enormous.

Source: "Wind Power Generation Guidebook" created by NEDO

Most wind turbines are manufactured by manufacturers in Europe and China, where wind power generation is becoming increasingly widespread, and the main models are large, with outputs of 3,000 to 4,500 kW, which are in high demand overseas. As a result, when Japanese power plants replace their existing turbines, it is difficult to obtain wind turbines with the same specifications as those originally adopted, with outputs of 500 kW to 1,500 kW, and they have no choice but to adopt larger turbines made overseas. For example, one power plant that previously operated nine wind turbines with an output of 1,650 kW each, for a total output of 14,850 kW, is now replacing them with four new large 4,300 kW wind turbines, ensuring roughly the same output as before.

Things to consider when wind turbines get bigger

If the replacement involves increasing the size of the wind turbine or changing its location, a new wind analysis must be conducted to determine the optimal location. It is also essential to check whether the increased size will cause interference with weather radar, aviation radar, and disaster prevention radio signals. Even if the turbine is being replaced in the same location, the existing concrete foundation must be demolished and removed, and a new, more robust foundation designed and constructed to accommodate the larger turbine. If the installation location changes and new land is to be developed on land not previously reserved for power plants, additional environmental impact assessments and land development and road construction costs may be required. Compliance with the Embankment Regulation Act, which came into effect in May 2023, is also required. Creating a replacement plan requires considering these various factors and making a comprehensive decision.

Issues in replacing wind power generation equipment

Replacing wind turbines requires them to be larger, which means there are many things to consider, but an even bigger problem is transporting the larger turbines to the site.

As we saw earlier, towers exceed 100 meters in height, reaching up to 120 meters in length. They are made of either steel or concrete, and although they are transported in sections and assembled on-site, each unit is still approximately 30 meters long. The blades are even more problematic. They cannot be disassembled. Blades are 45 meters long for 2,000kW-class turbines and approximately 65 meters for 4,500kW-class turbines. Furthermore, Japanese wind power plants are often located in windy mountainous areas, necessitating transportation along narrow, winding forest roads. This may require road widening and the felling of some trees along the road. Furthermore, if there is a bridge along the way, it must be checked to see if it can withstand the load of the wind turbine components, and reinforcement work must be considered if necessary. Even after transportation to the installation site, a temporary storage area for the components and a work space for assembling the turbine are required.

What PACIFIC CONSULTANTS can do

PACIFIC CONSULTANTS has been utilizing its comprehensive capabilities to handle a wide range of tasks related to the construction of wind power plants, including selecting suitable sites for the construction of onshore and offshore wind power plants, promoting understanding, wind condition surveys, master plans, design and construction plans, environmental assessments, and support for power plant operations.

In our wind simulations, in addition to the software generally used for certification, we also use software that can reproduce wind turbulence in more detail. This software can grasp in detail the wind vortexes known as "terrain turbulence" that occur due to the undulations of the terrain, so we can predict, for example, that "the expected average wind speed is high, but at this point the wind turbines will be exposed to turbulent winds frequently, and fatigue will accumulate more than expected," which increases the reliability of the plan.

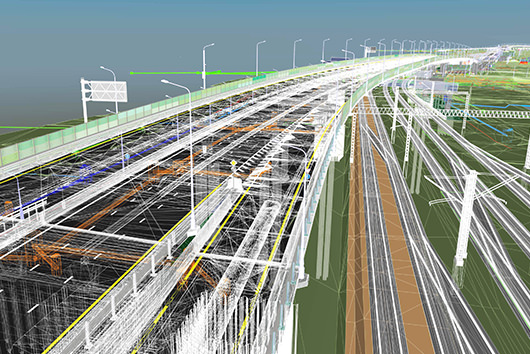

Another distinctive feature of our company's efforts is the active use of BIM/CIM in the creation of design and construction plans, including transportation. With BIM/CIM, design data can be shared and utilized in construction and operation, enabling efficient and advanced production and management. Regarding transportation, which is a major issue when replacing wind turbines, we can test drive transport vehicles on 3D model roads, which not only allows us to intuitively understand where the bottlenecks are and how to solve them, but also has the great advantage of being able to automatically calculate the amount of earthwork required.

Replacing onshore wind power generation inevitably involves enlarging the size of wind turbines. This requires linking various elements, such as new wind condition analysis, the formulation of plans and procedures related to civil engineering work, and transportation plans, to consider and formulate the most optimal plan, including cost. Only our company, with its specialized departments in-house and comprehensive capabilities that facilitate collaboration, can provide these considerations in a one-stop solution. Furthermore, because the ordering parties, such as local governments and businesses, can use our company as a single point of contact for overall consideration, they can obtain optimal solutions while improving operational efficiency. We will continue to utilize these comprehensive capabilities to contribute to the smooth replacement of onshore wind power generation.