With the promotion of BIM/CIM to improve productivity at construction sites, a major issue at present is the amount of work required to create BIM/CIM. In particular, how efficiently creating structural models can be achieved will have a major impact on future productivity improvements. This is why parametric models are now attracting attention. They are also entering the practical application stage in the world of civil engineering. We talked to four people at PACIFIC CONSULTANTS who are involved in the development and promotion of parametric models: Satoshi TOBIOKA of Erosion Control Dept. of the National Land and Infrastructure Div.; Masato KIKUCHI of Erosion Control Dept. and Advanced Technology Center; Tatsuji YAMAGUCHI of the Ports and Harbors Dept. of the same division; and Miho TANAKA of Ports and Harbors Dept. and Advanced Technology CenterWith the promotion of BIM/CIM to improve productivity at construction sites, a major issue at present is the amount of work required to create BIM/CIM. In particular, how efficiently creating structural models can be achieved will have a major impact on future productivity improvements. This is why parametric models are now attracting attention. They are also entering the practical application stage in the world of civil engineering. We talked to four people at PACIFIC CONSULTANTS who are involved in the development and promotion of parametric models: Satoshi TOBIOKA of Erosion Control Dept. of the National Land and Infrastructure Div.; Masato KIKUCHI of Erosion Control Dept. and Advanced Technology Center; Tatsuji YAMAGUCHI of the Ports and Harbors Dept. of the same division; and Miho TANAKA of Ports and Harbors Dept. and Advanced Technology Center, about the current situation and future development.

INDEX

- What is parametric design?

- Advantages of designing using parametric model

- PACIFIC CONSULTANTS' Initiatives

- Business Partnership with Dassault Systèmes

- 3D Simulation is also Possible

- Contributing to the spread of BIM/CIM through parametric model

What is parametric design?

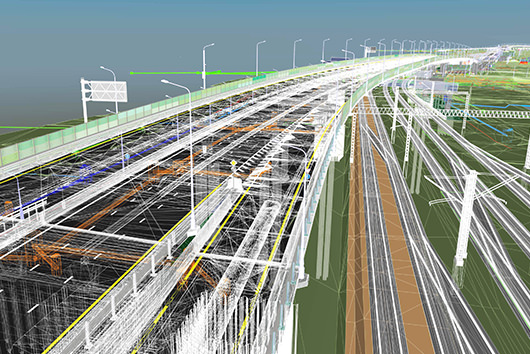

A BIM/CIM structural model is a 3D model that represents the terrain and shape of a structure in 3D, with attribute information such as component names, dimensions, and quantities added. Currently, structural models are almost always created from 2D drawings. However, this requires a great deal of effort, and if any corrections are needed, it is necessary to go back to the 2D drawings and make the necessary corrections, which creates a heavy workload and is prone to errors. In fact, there are complaints from the field that "creating BIM/CIM takes a lot of effort (time, money, and manpower)" and "it is necessary to create both 2D drawings and BIM/CIM." (Source: "How to Proceed with BIM/CIM," 12th BIM/CIM Promotion Committee, Document 1, July 26, 2024 (Ministry of Land, Infrastructure, Transport and Tourism))

This is where parametric models have become popular. They allow you to easily create structural models by simply entering corresponding numerical and other parameters into pre-prepared structural templates. Traditionally, they have been used in the fields of automotive, aircraft, and architectural design, but there is also a growing trend towards their use in the world of civil engineering structures. As a design method that does not involve 2D drawings, it can significantly reduce the amount of work required to create structural models.

To illustrate the concept of parametric models with a simple example, if you wanted to change the height of a cube, you would previously have had to modify the front and side views in 2D and then create a 3D model. However, with a parametric model, you simply place the height as X and enter a specified value there, and the modified cube will be generated as is. Furthermore, by creating a relationship between parameters, it is possible to change the shape in conjunction with changes in input values. For example, if the slope x height is the length in the depth direction, then when the height is 5m and the slope is 1:0.2, the depth is 1m, but if the height becomes 7m, the depth will automatically change to 1.4m.

With a parametric model, you can simply enter values into the template for the structure you want to design, and the structural model will automatically pop up. If you change some of the values, the entire 3D model will change accordingly.

However, our approach goes beyond simply inputting numerical values to manipulate shapes; by incorporating design rules that take into account the terrain and design conditions into the template, we are also able to support the rational placement of structures and design considerations. In other words, we are trying to use parametric models not just as an automated method for shape modeling, but also as a tool to make the design itself more advanced and efficient.

Advantages of Designing Using Parametric Model

Parametric models shift the focus from designing by "drawing blueprints" to designing by "inputting numerical values and design conditions," and can significantly reduce the amount of work required for design, such as by instantly creating 3D models and calculating quantities based on pre-installed design rules. This makes it possible to compare and consider more plans than ever before, and to propose optimal layouts. Of course, because parametric models express shapes in 3D, the design results are very easy to understand. Furthermore, since it is expected that consensus building with stakeholders can be achieved at the same time as the design, we believe that this will enable the rapid progress of urgent design work such as disaster recovery.

Furthermore, previously, structural models created were "one-of-a-kind" for that location and could not be applied to other sites. However, with a parametric model, the specifications required for design are stored in a template, so even if the site is different, a structural model can be automatically generated by entering the topographical information of the location and numerical values according to the template.

PACIFIC CONSULTANTS' Initiatives

PACIFIC CONSULTANTS has been working to develop this parametric model so that it can be used in the design of actual civil engineering structures, and has already achieved great results in the fields of erosion control and ports.

When designing a sabo dam, the specifications related to the facility's shape, such as facility location, dam height, water passage shape, crest width, and upstream/downstream slope, are set as parameters, and a 3D model can be generated by entering values here. The amount of concrete in the sabo dam can also be calculated automatically. In addition, calculations including topography can be processed quickly, so the amount of sediment that the sabo dam can hold back can also be calculated automatically at the same time. If the amount of sediment that can be held back is small, it is easy to consider changing the parameter values to change the dam height or the facility location. In fact, using parametric models in the outline and preliminary designs of sabo dams has produced great results.

We are also working to put parametric models into practical use not only in the field of erosion control but also in port-related facilities. Specifically, for the basic design of gravity breakwaters, we have developed a parametric model that, by inputting the topography and design conditions, performs stability calculations and draws the appropriate breakwater shape in 3D. We are currently working to increase the versatility of the developed model, with the aim of implementing it in design work.

Business Partnership with Dassault Systèmes

PACIFIC CONSULTANTS developed the parametric model using 3DEXPERIENCE CATIA (hereinafter referred to as CATIA), a 3D software provided by Dassault Systèmes of France.

CATIA is known for its high functionality compared to many other 3D CAD software programs. Its ability to handle terrain and structures in an integrated manner is particularly distinctive, and we felt it could meet our needs. Although it had not been used for the design of civil engineering structures in Japan, PACIFIC CONSULTANTS signed a business partnership agreement with us in the fall of 2019, and since then we have been working together to create parametric models for civil engineering structures.

3D Simulation is also Possible

Furthermore, we are developing technology that links parametric models not only to design but also to simulation. Previously, general-purpose software was available that could perform 3D simulations, but this required the time-consuming preparation of a separate simulation model and then running it through analysis software. If simulations can be linked to design, it will be possible to consider more effective facilities. For example, if a simulation reveals that there are areas prone to flooding, we can go back to the design, change the input values to alter the facility shape, and then run further simulations to verify its effectiveness.

For simulations, PACIFIC CONSULTANTS is considering using XFlow, fluid analysis software also from Dassault Systèmes. XFlow was originally used in the fields of fluid engineering in the automotive and aerospace industries, and has no track record in the civil engineering field, but they verified whether it would be possible to perform simulations by linking it with a BIM/CIM model created in CATIA.

Although it is still in the research and development stage, there is no doubt that the potential of parametric models will be further enhanced if it becomes possible to repeatedly perform design and simulation analysis on the same 3D model. In order to respond to the current trend in civil engineering design, which is the shift from specification regulations to performance regulations, parametric models that integrate design and simulation will become increasingly necessary in the future.

Contributing to the Spread of BIM/CIM through Parametric Model

Semi-automation of design using parametric models has entered the stage of on-site implementation through the use of CATIA. (Note: Parametric models themselves are a technology that has already been put into practical use in software other than CATIA.)

PACIFIC CONSULTANTS will continue to develop and deploy models that support the functions required for design studies in each field of civil engineering design. We also hope to further promote the use of parametric models in the construction consulting industry, contributing to improving productivity throughout the industry.