In April 2022, the "Act on the Promotion of Resource Circulation for Plastics" came into effect, requiring local governments to collect and recycle plastic waste other than plastic waste used for conventional containers and packaging in bulk. While there are some issues that need to be addressed, such as the need to review the collection and transportation system and the garbage collection calendar, the importance of this initiative is increasing in order to achieve carbon neutrality by 2050. We interviewed Takuma KANO from the Resource Circulation Management Dept.,Atsushi TAKENOUCHI from the DX Business Promotion Dept. , and Gou YAMAMURA from the Disaster Prevention Dept. of PACIFIC CONSULTANTS, who provide various consulting services, including analysis of the current situation, identification of issues, and operation management systems for collection vehicles, to ensure smooth implementation of bulk collection.

INDEX

- Overview and background of the New Act on Plastics

- What has changed with the New Act on Plastics?

- Challenges that local governments are facing

- PACIFIC CONSULTANTS' Initiatives

Overview and background of the New Act on Plastics

In the past, plastics used in containers and packaging were collected by local governments and remanufactured and recycled at the expense of business sectors, based on the "Act on Recycling Containers and Packaging" that came into effect in 2000. However, plastic products other than containers and packaging were not subject to the Act, so local governments handled them in various ways, such as collecting and landfilling them as non-burnable waste, or incinerating them as burnable waste and using them as a source of thermal energy, and there were only a limited number of local governments that collected and recycled them as plastic waste on their own. In addition, there were many complaints from consumers, such as "It's hard to understand how to separate them" and "It's a waste to throw away plastic products even though they're the same plastic."

Meanwhile, the recently enacted "Act on the Promotion of Resource Circulation for Plastics" (hereinafter referred to as the New Act on Plastics) calls on all relevant parties, from product design to plastic waste processing, to take measures for plastic resource circulation, with the aim of reducing the amount of plastic used and further strengthening resource circulation, against the backdrop of issues such as the worsening problem of marine plastic waste, the increase in CO2 emissions due to incineration, and the strengthening of import regulations on plastic waste in China and Southeast Asian countries. Although there have been systems in the past that call for the recycling of products such as televisions, refrigerators, washing machines, air conditioners, and even computers, the major feature of the New Act on Plastics is that it calls for the 3Rs + Renewable (replacement with renewable resources) for the material itself, which is plastic, and calls for the reduction of plastic use and resource circulation for all plastic materials.

What has changed with the New Act on Plastics?

The New Act on Plastics stipulates three new initiatives: the first is environmentally conscious design in design and manufacturing, the second is rationalization of use in sales and provision, and the third is separate collection and re-commodification in the disposal, recovery and recycling stages.

|

Design/Manufacturing |

Establish guidelines for environmentally conscious design that manufacturers should strive for, certify products that meet those guidelines, and have the government take the lead in adopting them. |

|

Sales/Provision |

Establish criteria for suppliers of single-use plastics (such as spoons and forks distributed at retail stores) to follow, and make recommendations, public announcements, and orders based on those criteria. |

|

Disposal/Collection/Recycling |

In addition to separate collection and recycling in municipalities, we will encourage voluntary collection and recycling by manufacturers, retailers, and waste generators. |

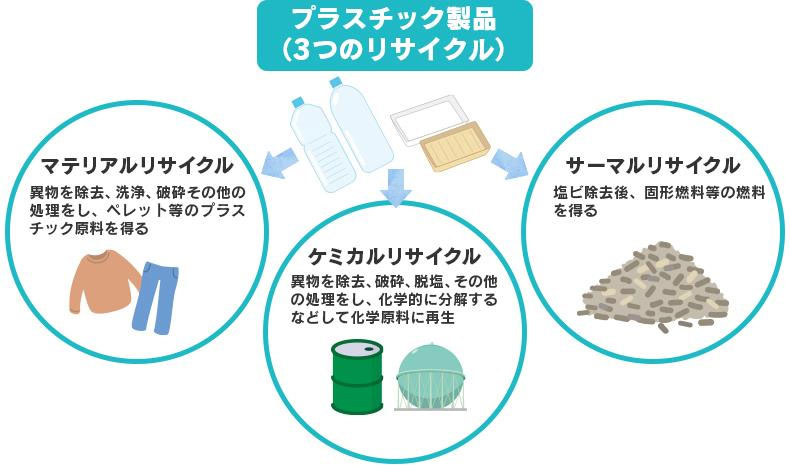

Municipalities are now required to collect not only plastic waste as specified by the previous Act on Recycling Containers and Packaging, but also general plastic waste (buckets, dustpans, cleaning product packaging, hangers, etc.) and recycle it through one of the following two routes. One is to entrust the collection to a designated corporation under the Act on Recycling Containers and Packaging, and the other is to formulate a recycling plan individually or jointly and recycle it after receiving national certification. There are three main recycling methods as shown below, but when plastic is collected, thermal recycling is only used in emergency situations, and it is basically recycled through material recycling or chemical recycling. Thermal recycling has a lower priority than these, and this applies to waste-to-energy projects, in which dirty plastic waste is treated as combustible waste.

|

Recycling Methods |

Content |

|---|---|

|

Material Recycling |

Foreign substances are removed, and the plastic is washed, crushed, and otherwise processed to obtain pellets and other plastic raw materials. |

|

Chemical Recycling |

Foreign substances are removed, the waste is crushed, desalted, and otherwise processed, and then chemically decomposed to regenerate it into chemical raw materials. |

|

Thermal Recycling |

After removing the PVC, solid fuel and other fuels are obtained. |

The bulk collection and recycling of plastic waste by local governments that came into force with the enforcement of the New Act on Plastics is a guideline for the handling of waste plastic, and is a voluntary obligation with no binding force. In addition, there are various issues involved, such as the incurring of new costs, and we believe that such efforts will become more widespread in the future.

However, with the enforcement of the New Act on Plastics, the Ministry of the Environment has added a new requirement for the grant for promoting the creation of a circular economy, which is "Implementation of the separate collection and recycling of plastic resources in accordance with the New Act on Plastics," for the development of major facilities such as the construction of material recycling promotion facilities, energy final landfill site waste treatment facilities and final disposal sites, as well as core equipment improvement projects for waste treatment facilities.

This subsidy is a large amount, covering one-third of the costs required for facility construction (one-half for advanced facilities such as highly efficient energy recovery facilities), and will be a major boost to facility construction. Since it is basically difficult to build facilities without utilizing the subsidy, it is no exaggeration to say that the collective collection and recycling of plastic waste is practically mandatory. Even if there are no plans for facility construction in the near future, there are many issues that need to be considered in planning for the collective collection and recycling of plastic waste, so we believe it is desirable to begin consideration of this in advance.

Challenges that local governments are facing

One of the biggest problems for local governments in implementing the bulk collection of plastic waste is how to deal with the increased workload that comes with bulk collection. While collecting and transporting burnable and non-burnable waste as usual, they must collect plastic waste (plastic waste under the Act on Recycling Containers and Packaging) separately. Therefore, whether they collect plastic waste on the same day as burnable and non-burnable waste or set a separate collection day, the amount of plastic waste generated from households will definitely increase, and the workload of businesses will also increase, which is likely to affect collection and transportation costs. In addition, since it is necessary to avoid increasing the burden on citizens as much as possible, it is also important to devise ways to have plastic waste put out on the same cycle as before, without changing the existing garbage collection calendar as much as possible.

Furthermore, sites that have already undertaken the "Advanced Model Formation Project" have reported that toys and other items need to be checked one by one to see if they have any metal parts such as screws attached or if they have any batteries still inside, resulting in a heavy workload.

There have been cases where built-in batteries have caused fires in collection vehicles and treatment facilities, making it clear that bulk collection of plastic waste does not simply increase the amount of waste, but also increases the amount of work required, and that safety measures for workers and treatment facilities are also important.

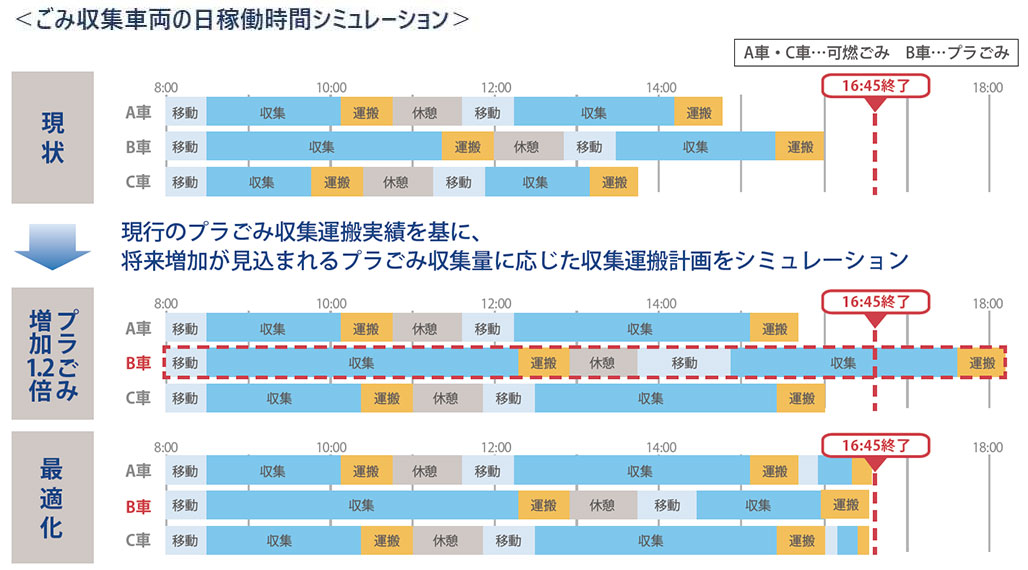

As is clear from the trial results of the model project, the first thing required for bulk collection of plastic waste is to devise an efficient operation plan for collection vehicles. In order to smoothly proceed with collection in response to the increase in waste volume and collection work, it is essential to consider how many collection vehicles should be operated and what routes they should take.

To do this, it is necessary to first analyze the current situation, but we believe that many local governments do not have a grasp of their current operation details. If only basic information such as how many times a week and on what days collection is done, and by what time it is brought to the designated treatment plant, is known, it is difficult to make a well-founded judgment on how much operation can be increased, whether it is already at its limit, and how many vehicles would be needed if additional vehicles were to be added. In order to reduce the financial burden, it is desirable to keep the increase in the number of vehicles as low as possible, so first it is necessary to clarify the current state of waste collection, and then to design an efficient system and routes.

PACIFIC CONSULTANTS' Initiatives

PACIFIC CONSULTANTS, which supports local governments in planning and implementing various policies, including infrastructure maintenance, is also providing support for the bulk collection of plastic waste across the country.

One of these is understanding the operational status of waste collection vehicles and clarifying current issues. Based on GPS data on the operation of collection vehicles and location information on waste stations and treatment facilities, the current operational status and CO2 emissions are visualized, and it is made clear how much capacity there is to handle if bulk collection of plastic waste is implemented.

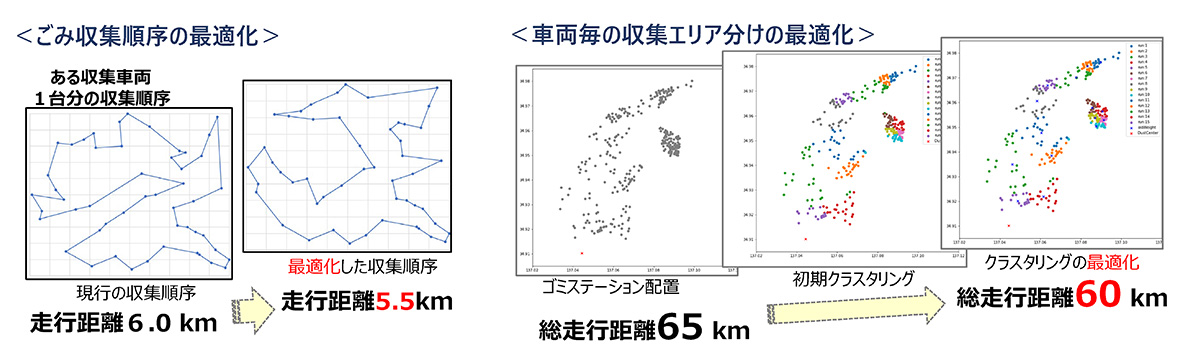

Furthermore, we are proposing efficient operation plans by creating optimization proposals for the "collection order of garbage stations" and "collection area for each garbage collection vehicle," using the travel distance and operating time of garbage collection vehicles as evaluation indicators, such as in what order to visit the garbage stations to minimize travel distance, and how to divide the collection areas for each vehicle to reduce the overall travel distance.

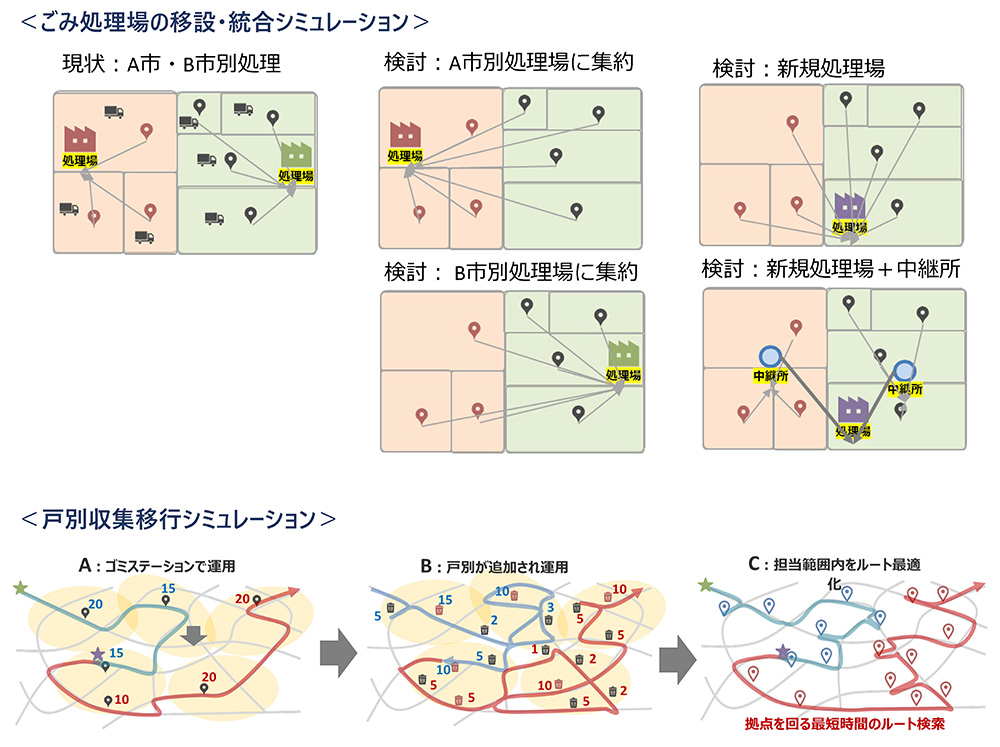

In addition, we conduct simulations of the total operating hours of waste collection vehicles when implementing bulk collection, consolidation or relocation of waste treatment plants, etc., and support consideration of the required number of vehicles and optimal establishment.

The company is also developing an online service system that will monitor waste collection status in real time to detect delays or omissions in collection, and consolidate inquiries and information from citizens and reports from collection workers into a database for centralized management, thereby improving collection schedules, detecting delays, and making it easier to respond to inquiries from citizens.

In one case, a local government carried out a detailed simulation to determine how many collection vehicle operations would be required if they were to start a new bulk collection of plastic waste, and provided support for establishing a collection system. There was also a case where we helped select candidate sites for new recycling facilities and organize business conditions by examining them together with collection and transportation operations, narrowing down the optimal options and leading to the subsequent basic design.

PACIFIC CONSULTANTS will also consider the following initiatives in relation to the digitalization of waste collection and transportation. For example, automatically creating improvement plans for waste collection and transportation routes based on daily operation records, and combining this with autonomous driving to quickly respond to route change instructions. In addition, the company aims to provide value-added services that comprehensively improve local government services, such as using collection and transportation vehicles as sensors that run through town to automatically monitor abnormal phenomena caused by the aging of social infrastructure, which has become a recent problem.

PACIFIC CONSULTANTS also has a specialized department for PPP, and has a wide range of expertise, including transportation policy, urban development, environment and energy, and vehicle operation management using digital technology, and its engineers in each field bring together their experience and knowledge to support local government policies through integrated solutions. They will also contribute to policy planning for bulk collection of plastic waste and construction of treatment facilities.