Have you ever thought about the underground infrastructure that lies beneath your feet?

Sewerage pipeline facilities are steadily deteriorating. Unless immediate action is taken, there are concerns that there will be an increase in road collapses caused by sewerage systems and adverse effects on society due to malfunctions.

As we move from the era of construction to an era of full-scale maintenance and management, we would like to consider what we can do to sustain a safe and secure sewerage business.

INDEX

- Issues facing sewerage infrastructure

- Taking on the challenge of effective stock management through overall optimization and visualization

Issues facing sewerage infrastructure

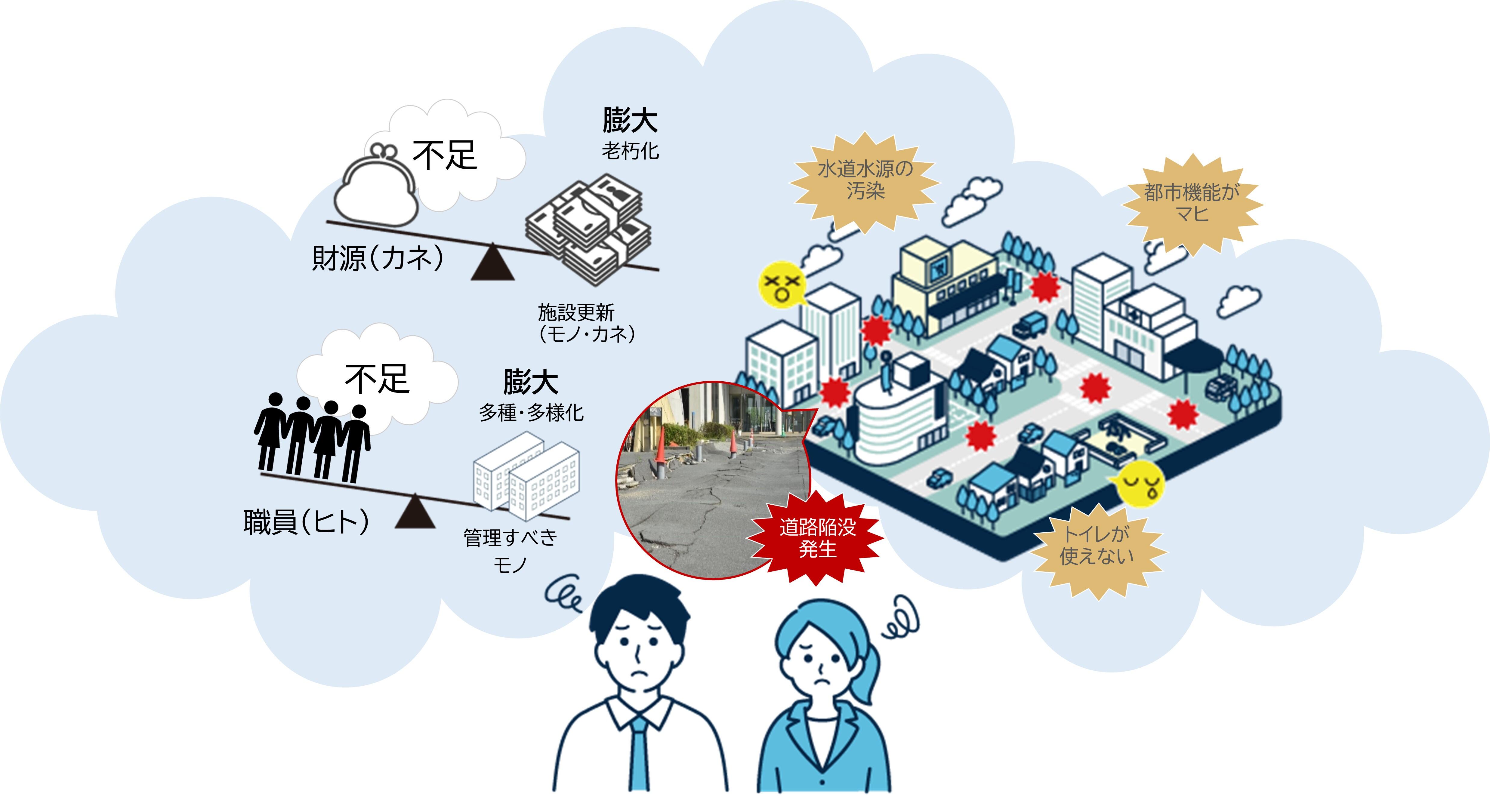

Sewerage facilities are expected to face rising maintenance and renewal costs due to their aging, while a shortage of human resources and financial resources is predicted due to the declining birthrate and aging population.

In addition, because sewerage pipe facilities are buried underground and it is not possible to monitor their deterioration, they have traditionally been maintained on a "reactive" basis, responding only after an incident (such as a blockage or collapse) has occurred. However, it has become clear that the rate of road collapses in sewerage pipes that were installed more than 30 years ago is increasing significantly, and this is beginning to have a significant impact on the lives and social activities of residents.

Against this background, the government established the Stock Management*1 Support System in fiscal 2016.

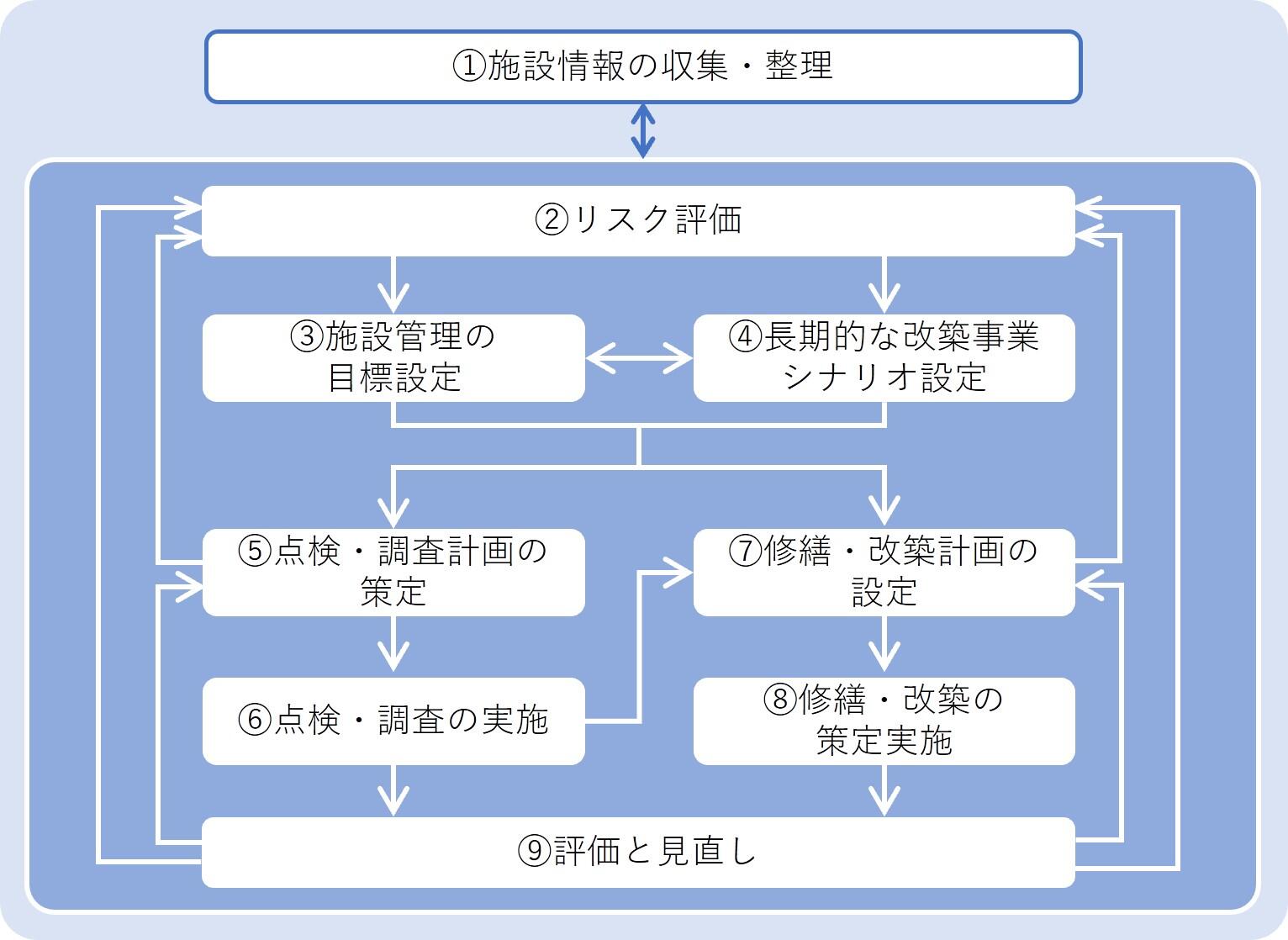

Based on this system, each local government has started to develop and implement a stock management plan and transition to a "preventive maintenance" type of maintenance. However, since inspections and surveys were hardly carried out in the past in the reactive maintenance, the development of stock management plans was based on desk data (for example, the year of installation and the size of the pipeline), which resulted in cases where there was a discrepancy between the actual state of the pipeline and the current state assumed at the time of planning.

Therefore, in order to practice efficient and effective stock management that is in line with actual conditions in the future, it will be important to utilize the data from inspections, surveys, and other data that is beginning to be accumulated through preventive maintenance.

Additionally, as a country, we are also starting initiatives to promote integrated management of maintenance and renewal through Water PPP*2.

Under these circumstances, in order to put into practice efficient and effective stock management, our company has been accepting orders from local governments for "Comprehensive Private Outsourcing of Sewerage Pipe Facilities*3" (hereinafter referred to as "Comprehensive Outsourcing") since fiscal 2015. We aim to optimize (minimize) risks within the limited budget and work to operate the business in a feasible manner.

This time, I will introduce the contents.

Taking on the challenge of effective stock management through overall optimization and visualization

1. Aiming for effective project implementation (best mix of inspections and surveys) aimed at "total optimization"

The contents of the stock management plans formulated by each local government vary depending on the local government's circumstances (budget, amount of facilities owned, number of years since installation, staffing structure, etc.).

Among these, a relatively common plan is to select high-risk sewerage pipes (old pipes, large-diameter pipes, pipes laid along important roads, etc.) based on desk data, and then conduct detailed inspections one by one while prioritizing them. If the inspection reveals any pipes in poor condition, they will be renovated or updated. A high risk means there is a high possibility of them breaking, and if they do break, the impact on the surrounding environment can be enormous, so this is a very effective plan.

However, seven years have now passed since the stock management support system was launched, and detailed surveys have been conducted on pipelines that were assumed to be high risk on paper, but it has been discovered that in reality, many of the pipelines are in good condition. It is not necessarily the case that "old" means "deteriorating," and there are quite a few cases where there is a discrepancy between the data on paper and the actual situation on the ground.

On the other hand, there have been cases where deterioration has progressed even in new pipelines depending on the environment and conditions in which they are installed.

In this situation, there are concerns that conducting detailed surveys of all pipelines as has been done in the past would take a huge amount of time and cost, resulting in inefficiency.

We are considering ways to resolve these dilemmas efficiently and effectively, and aim to support sustainable sewerage operations through the formulation of stock management plans.

So, let's think about it in terms of the human body as an image.

I think that a preventative measure, especially if you have no subjective symptoms, is to have a regular annual health check. Health checkups are a very effective way to understand the overall condition of your body regularly (frequently) at low cost.

The stock management plan that we implement is like a "health check (overall optimization)."

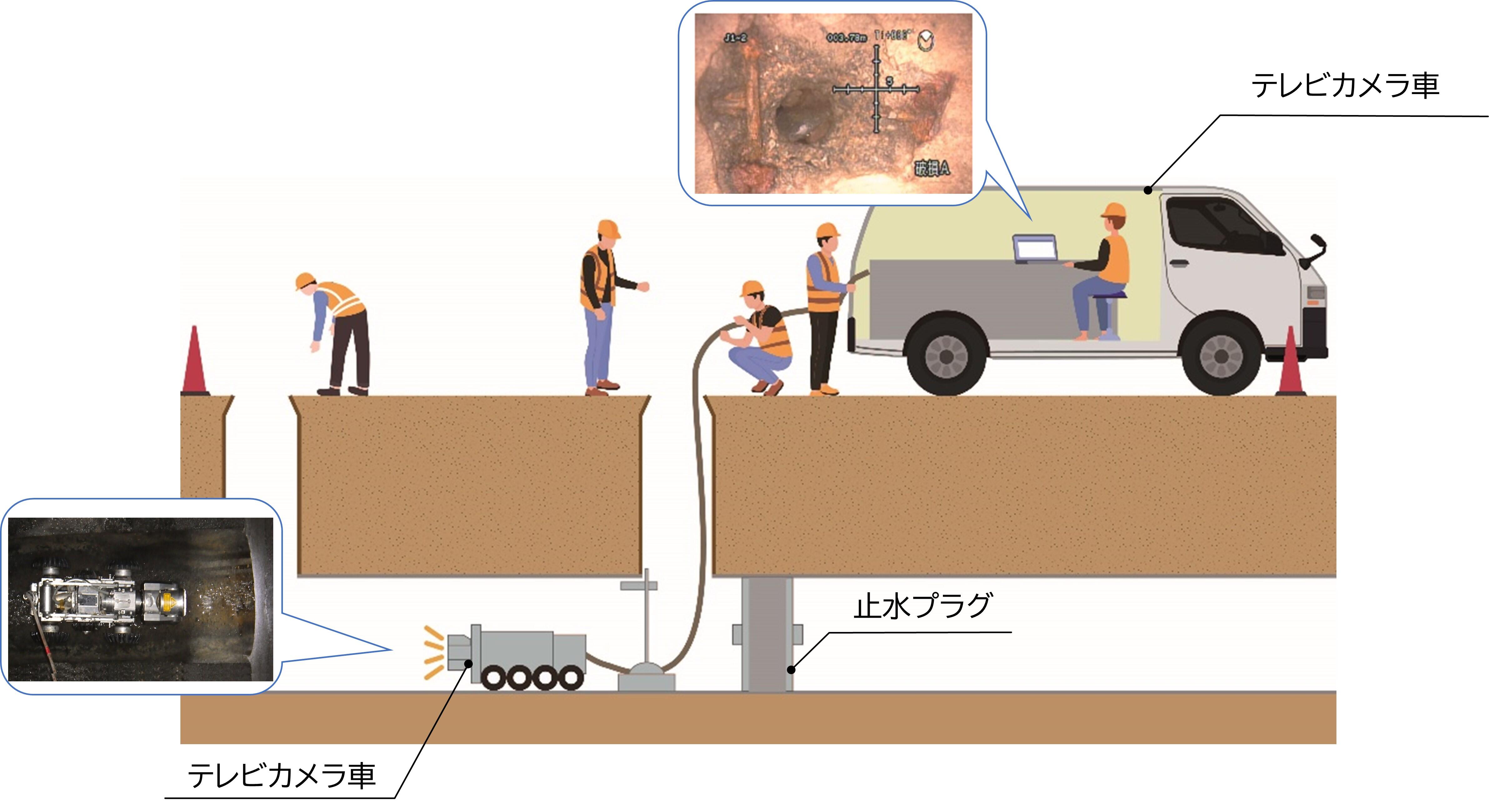

The aim is to collect inspection data from the entire area using simple methods (such as pipe opening camera inspections) that allow for quick, frequent, low-cost inspection of pipeline facilities where problems are invisible and have not yet become apparent, and then analyze and evaluate the data to efficiently and comprehensively identify potential risks.

On the other hand, if a poor pipeline is found during a pipe opening camera inspection or a pipeline posing a high risk, it is also important to conduct a detailed inspection to prevent major accidents from occurring.

In order to maintain a healthy body (sewerage facility) forever, we believe it is extremely important to continue to undergo thorough "health checkups (overall optimization)" within limited time and money, while also conducting "precise examinations (partial optimization)" in a balanced manner as necessary.

Here are our company's initiatives for that purpose

Optimizing life cycle costs (LCC) by making invisible facilities visible

In order to achieve the "total optimization" mentioned in the previous section, it is important to collect as much inspection and survey data as possible throughout the entire area and to make visible the sewerage pipe facilities that are buried underground and therefore cannot be seen.

Our company has been entrusted with comprehensive outsourcing in Fuji City, Shizuoka Prefecture since 2015, and in Kashiwa City, Chiba Prefecture since 2018, and is aiming to optimize (minimize) LCC through trial and error in making sewerage pipeline facilities more visible.

Here we introduce some of these techniques.

(1) Visualization using hazard maps

The entire area is divided into meshes (for example, 500m x 500m meshes) to grasp the deterioration status on a surface level, not on a per-span basis, but on a mesh-by-mesh basis. By color-coding the deterioration status, it is possible to visually determine in which areas deterioration is progressing (this diagram is called a hazard map).

For example, you can plan to conduct detailed surveys of the red and orange meshes in the hazard map on the right, which show a high rate of deterioration.

(2) Deterioration prediction (calculation of expected life of pipelines)

Based on accumulated inspection and investigation data, it is possible to predict the expected lifespan*4 for each of the meshes mentioned above. Based on the prediction results, it is also possible to calculate the amount of investment required in the future in detail.

The figure below shows an example (image) of a scenario pattern that reflects the results of analysis and evaluation that significantly reduced investment costs compared to renewing concrete pipes based on the standard service life of 50 years.

(3) Minimizing life cycle costs (LCC)

By accumulating a large amount of data and conducting analysis and evaluation as described above in ① and ②, it becomes possible to flexibly formulate scenario patterns for renewal plans that will require future investments.

The figure below shows an example (image) of a scenario pattern that reflects the results of analysis and evaluation that significantly reduced investment costs compared to renewing concrete pipes based on the standard service life of 50 years.

(4) Continuously improve stock management using comprehensive outsourcing

So far, we have introduced some of the stock management plans that we are implementing, but our preventive maintenance efforts have only just begun, and it will be necessary to continue accumulating inspection and survey data in accordance with the budget scale of each local government.

A stock management plan is not something that is completed once it has been formulated; it needs to be refined using the PDCA cycle, and it is also important to establish the means to do so.

One of these is comprehensive outsourcing.

The government also believes it is important to manage maintenance and renewal in an integrated manner, and is promoting water PPPs through the PPP/PFI Action Plan (revised for 2023).

2. Promoting DX (Digital Transformation)

Recently, we hear about DX in various fields. Our company is also actively working on DX.

In the past, in sewerage projects, inspections, surveys, cleaning, repairs, etc. (hereinafter referred to as "maintenance") were ordered separately, which meant that the formats of reports were inconsistent and paper-based management was the norm.

This made it difficult to find the necessary information among the vast amount of past maintenance data, and led to the issue of not making use of the data that had been accumulated.

Therefore, we are working on digital transformation to ensure that we create a database of "utilizable data" and to improve the efficiency of its maintenance.

3. Local companies play a key role in the maintenance of sewerage pipe facilities

To realize a sustainable sewerage system, it is extremely important that local companies and human resources play a central role in supporting the maintenance and management of sewerage facilities.

Local businesses act as a sort of local doctor, responding immediately to the needs of residents (such as complaints) and providing constant support.

Our company supports local companies by providing optimal policies through health checkups, management of electronic medical records using digital transformation, and efficient information sharing, and we operate our business in close collaboration with the local community.

4. Past and Future

Through comprehensive outsourcing in Fuji City, Shizuoka Prefecture, Kashiwa City, Chiba Prefecture, and Suita City, Osaka Prefecture, our company has accumulated practical know-how in areas such as inspection, analysis and evaluation methods and stock management, and is constantly improving this know-how.

Leveraging this experience, in 2023, the company was recognized for its outstanding social contribution efforts in "making invisible sewer pipes visible" as part of a comprehensive outsourcing project with Kashiwa City, and was awarded the Minister of Land, Infrastructure, Transport and Tourism Award "Circulation Path Sewerage Award (Circulation Path Sewerage Award/Ministry of Land, Infrastructure, Transport and Tourism website: https://www.mlit.go.jp/mizukokudo/sewerage/content/001629190.pdf)."

We will continue to combine our knowledge, track record, and ever-advancing new technologies to address increasingly diverse and sophisticated needs.

In addition, by utilizing the Group's strength, namely its know-how in the infrastructure field, we would like to expand beyond comprehensive sewerage systems to include comprehensive road systems and Power Producers and Suppliers (PPS) companies, aiming to realize "area management" through collaboration and co-creation across industry boundaries.

We will continue to contribute as a partner that fundamentally supports the realization of a sustainable, safe and secure society.

- *1 Stock management is the process of objectively grasping and evaluating the overall status of sewerage facilities and managing them in a planned and efficient manner while predicting future facility conditions.

- *2 Water PPP is a PPP method for gradually transitioning to concession projects for water supply, sewerage, and industrial water supply, and is a method of managing operation and renewal in an integrated manner.

- *3 Comprehensive private outsourcing refers to the comprehensive outsourcing of multiple operations and facilities to private businesses so that they can efficiently and effectively operate multiple maintenance and management tasks that have been primarily handled by the public sector up until now by utilizing their ingenuity and know-how.

- *4 Expected life is the period during which the product can be used without any practical problems under standard conditions.